04

Industrial Knives

Metal industry

/ 04 SERVICES

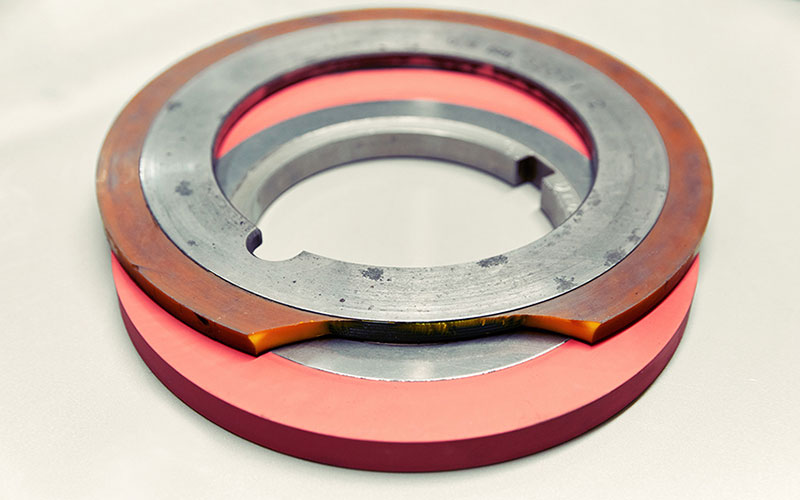

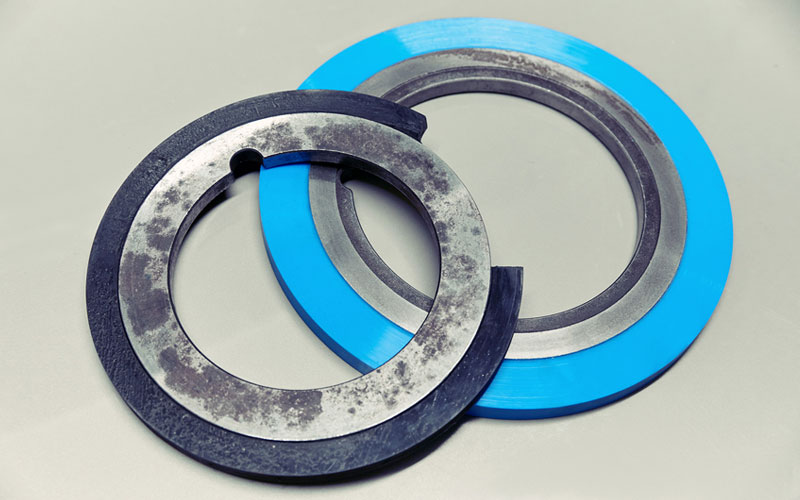

4.A KNIFE GRINDING SERVICE

Every cutting element is subject to wear, due to friction and the nature of the application.

Depending on the type of knife and its use, it is possible to regenerate it by means of a sharpening/re-grinding process.

- Slitter knive grinding service

- Shear blade grinding service

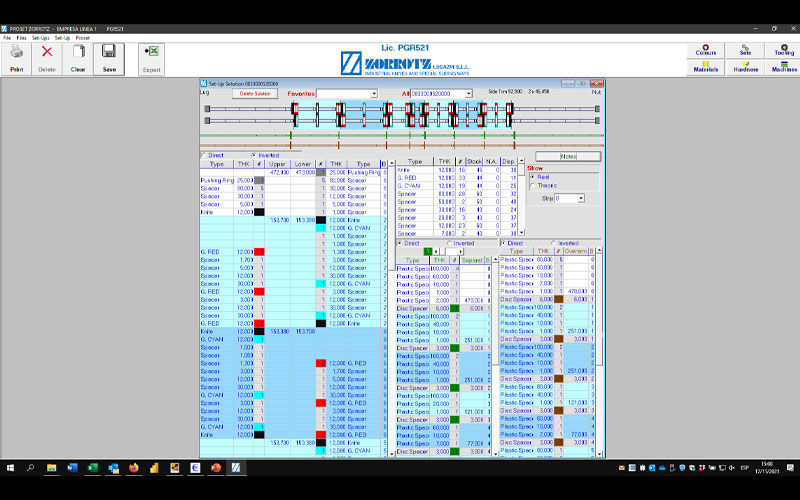

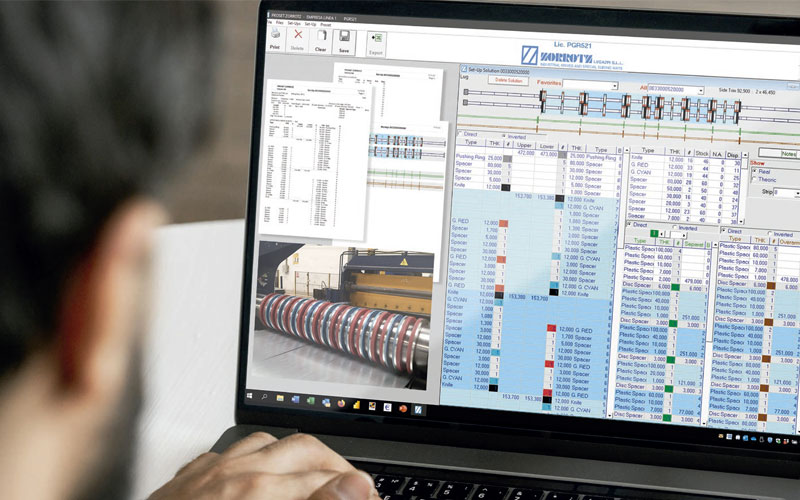

4.C PROSET

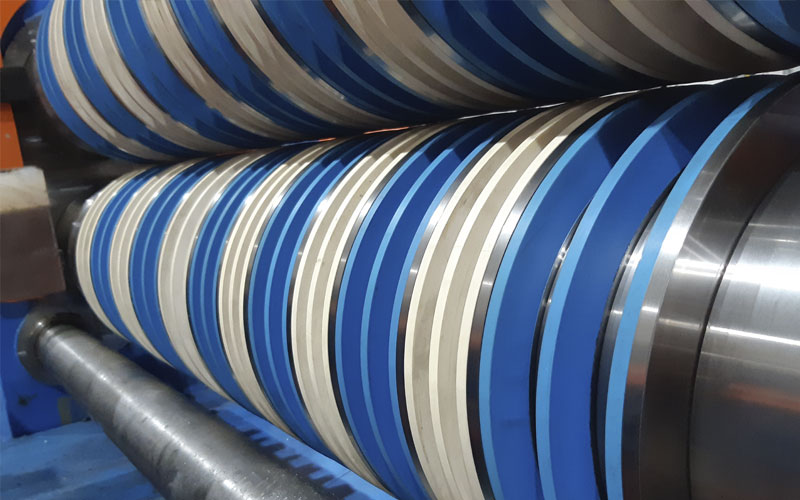

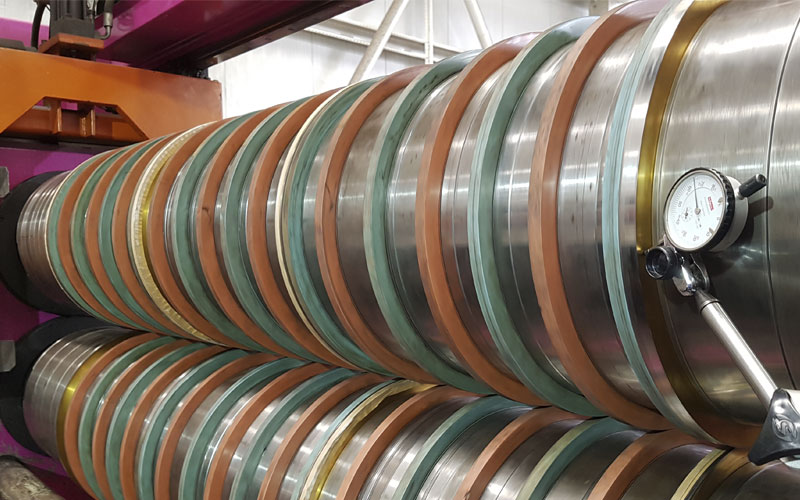

Thanks to the experience accumulated in the manufacture of slitter tooling, we have developed the PROSET application for the calculation of the tooling setups.

The application has been created to optimise the number of spacers used, with the aim of reducing assembly times and, at the same time, ensuring that setups calculations are prepared with the maximum accuracy preventing possible errors.

It allows for an exhaustive configuration of cutting parameters and tooling characteristics (thicknesses, colours, clearances, etc.) which allows the results to be customised according to the working habits of each customer. Allows data exchange with both ERP Software and assembling automated systems. Thanks to the “tooling reserved” option, it is possible to simulate the simultaneous assembly of several setups and, as a consequence, find the best solution taking into account the elements “not available”.

The result of the calculation can be printed or displayed in different formats. We offer installation and training services, both on-site and online.

PROSET is continuously updated and is compatible with Microsoft Windows operating systems. It is available in several languages and can be configured for use in different units (metric or imperial).

4.E CONSULTANCY AND TRAINING

We make our experience in metal shearing and slitting

process, available to customers. We deliver customised

consultancy sessions, in the form of on-site courses, where we train customer workforce on specific topics,

covering a wide range of scenarios.

Training

- Slitter tooling optimization

- Knives / Blades wear analysis

- Use and optimization of rubber bonded system

- Slitting and shearing problem analysis

- PROSETSoftware Training

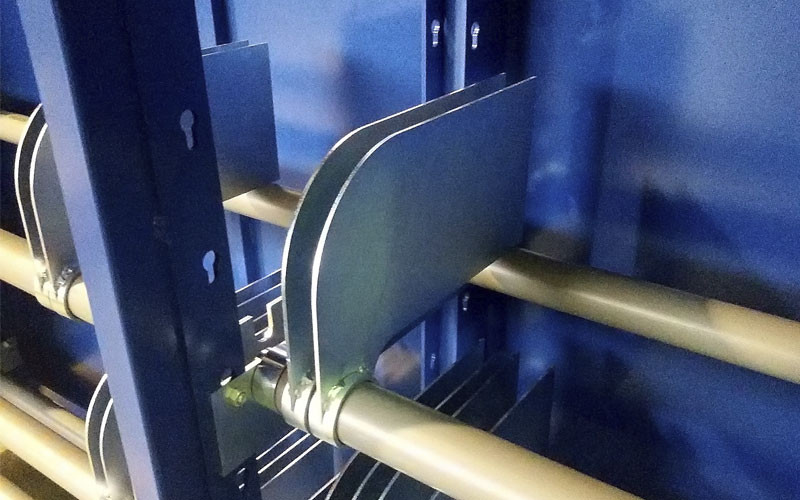

4.F CUTTING PARAMETERS ANALYSIS (CPA)

We carry out an extensive Cutting Parameters Analysis (CPA) at the customer’s site prior to the start-up of the tooling. We can also help the customer to search for the origin of specific cutting issues.

We cooperate with the slitter machine manufacturer at tooling star-up. (Slitting line and shearing machine, tooling commissioning…).

We carry out several measurements to check:

- Measurement and inspection of tools used

- Shaft measurement

- Starting “zero point” alignment

- Knife general dimensions and tolerances